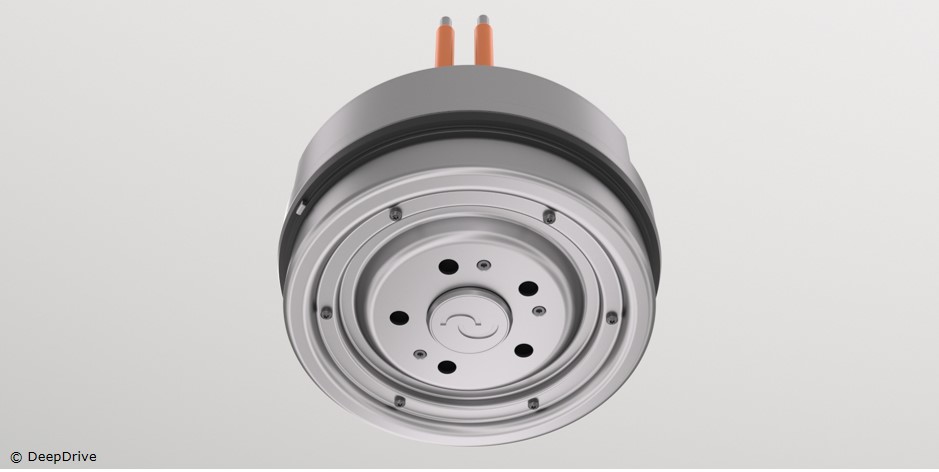

Researchers at TU Bergakademie Freiberg in Germany have developed a technology which uses artificial intelligence (AI) to disassemble electric motors for recycling and recognize reusable components. The process aims to recover strategic raw materials contained in electric motors, such as the rare-earth metal neodymium. Current recycling methods are not yet able to extract these raw materials effectively.

More efficient recycling and a better carbon footprint

The dynamic image recognition of parts and components with the help of AI enables robot-assisted disassembly and sorting of the individual parts, thus improving recycling efficiency and reducing the carbon footprint of electric motors. The new technology allows components to be separated by type and optimizes the personnel’s workload.

Lightweight technologies for the energy transition

The innovative process is part of the TU’s ongoing “Lightweight Construction Technologies for Cross-Life Cycle Products of the Energy Transition” (LIKE) research project. In collaboration with partners such as Siemens, the Institute for Processing Machines and Recycling Systems Technology is working on the development of recyclable electrical machines.