ercedes-Benz is planning to double its production capacity for electric drives at the Untertürkheim site. Originally, up to 500,000 units per year were to be manufactured there. Now the company is aiming for annual production of up to one million units. Daimler has officially confirmed the expansion and signed a works agreement between the works council and company management. Production of electric drives is expected to start at the end of 2024.

Increasing the share of added value

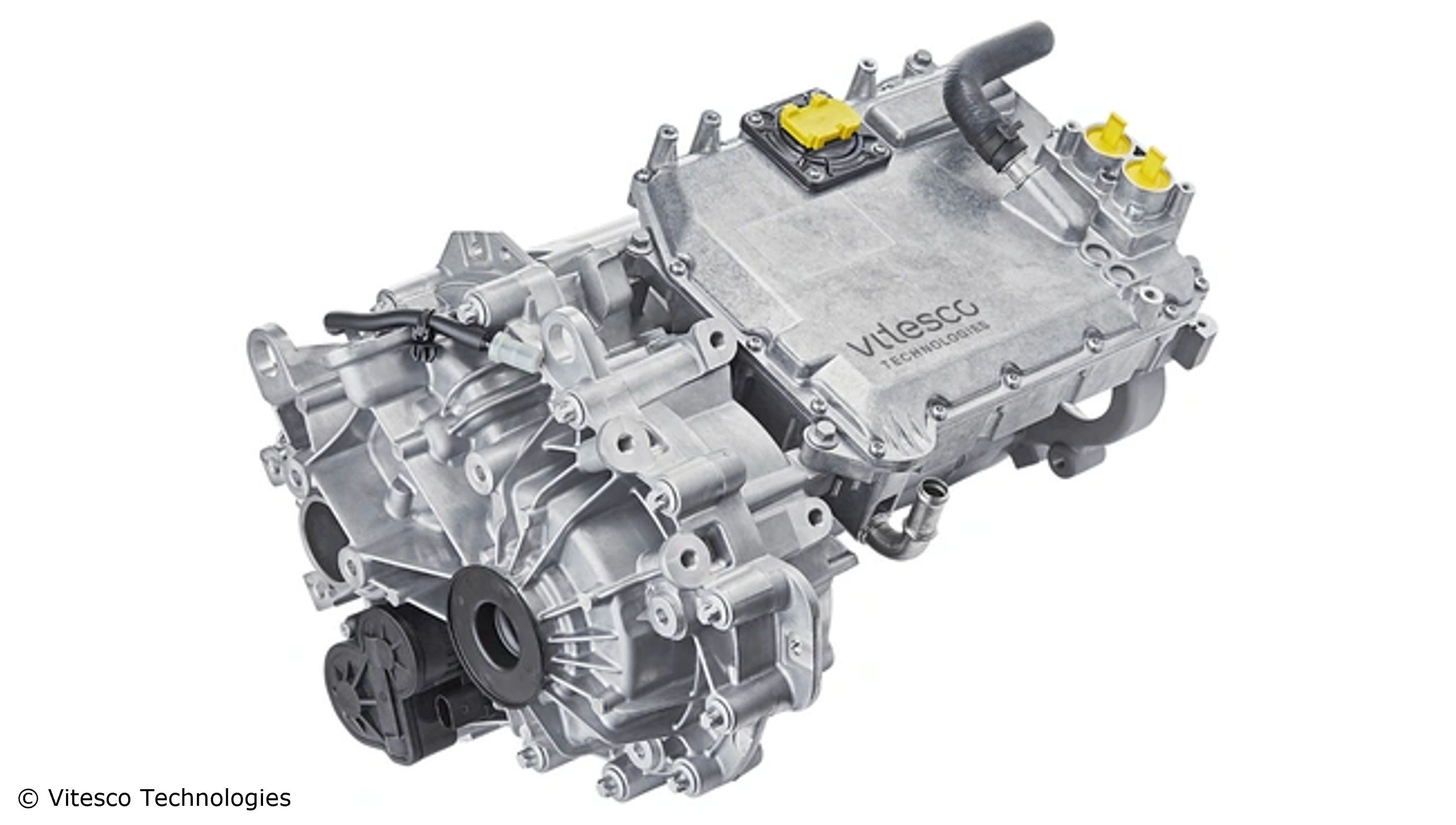

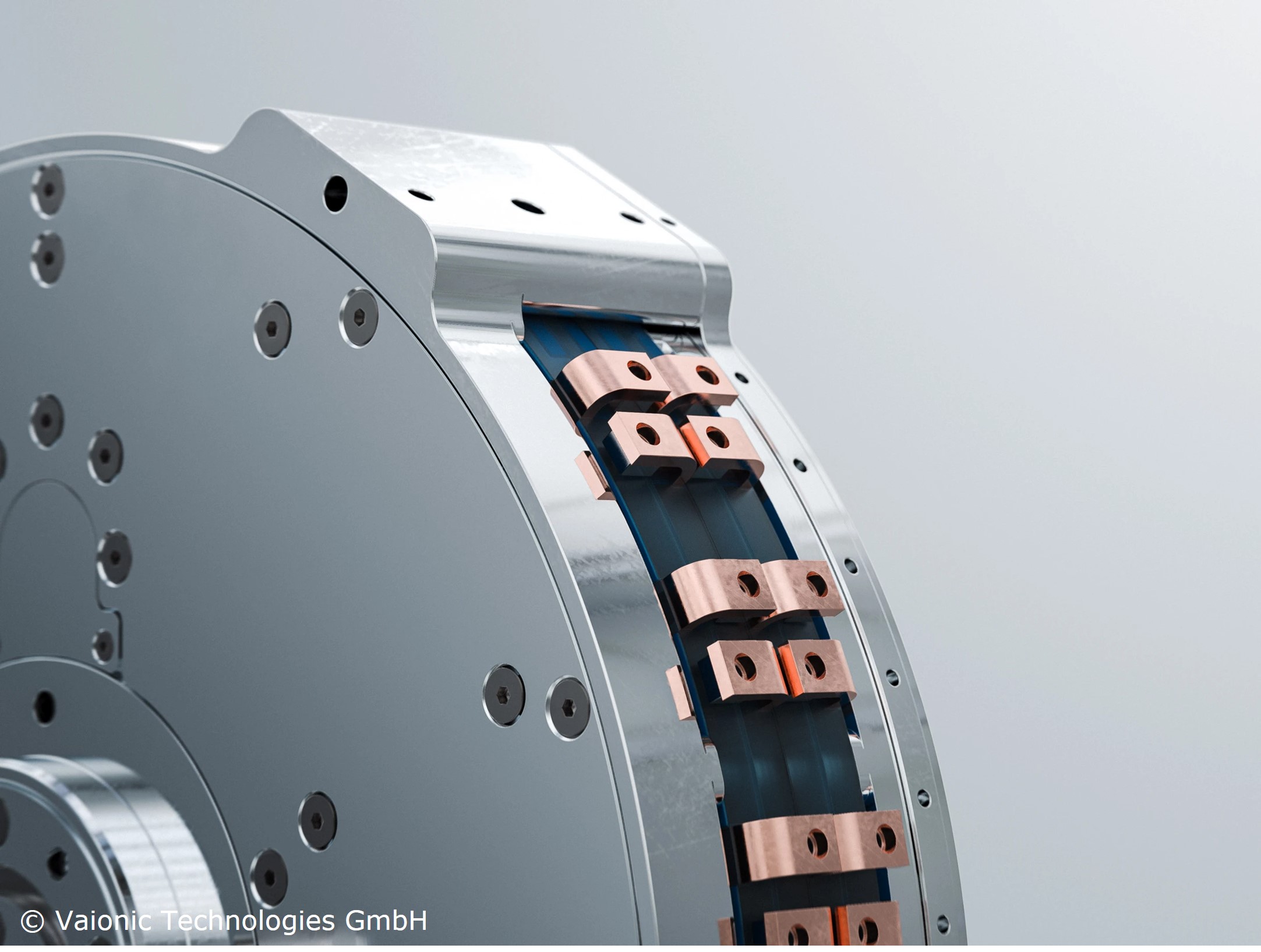

The Untertürkheim facility is a location for the production of batteries and axles for plug-in hybrids and fully electric Mercedes EQ models. The goal of Mercedes-Benz is to increase the proportion of added value and to produce drive technologies in-house. To this end, the company acquired British electric motor specialist Yasa in 2021 in order to gain access to axial flux motor technology.

Strategic expansion and electrification plans

With the expansion of production targets in Untertürkheim, Mercedes-Benz is continuing its strategy of developing and manufacturing its own electric motors. Construction of the new assembly lines is scheduled to begin in 2025. The electric drive components are to be manufactured in Untertürkheim, Hedelfingen, and Mettingen. Mercedes-Benz plans to solely produce electric drives by 2030 and to manufacture new series of platforms specially developed for electric vehicles from 2024/2025. The new generation of the E-Class is set to be the last Mercedes-Benz model to be based on a pure combustion engine platform.