Electric motors play a key role in the mobility transition due to their high efficiency and zero emissions during operation. However, their weight, the installation space required to accommodate them, and, above all, their energy consumption have a significant impact on the ecological footprint of a vehicle. A decisive factor for the efficiency of an electric motor is the utilisation of the installation space for the copper windings in the stator. In order to increase this, the Fraunhofer IWU has developed a forming manufacturing process for the production of concentrated single-tooth coils. While the utilisation factor, also known as the slot fill factor, is around 50 % for conventional single-tooth windings, this can be increased to almost 80 % using the layer-adapted structure. This significantly increases the amount of copper available for generating the magnetic field and thus the torque, which in turn leads to a higher power density. The higher power density makes it possible to build the motor smaller, lighter and more compact with the same output, thereby reducing costs and material usage.

Innovative forming technology enables layer-matched winding structure

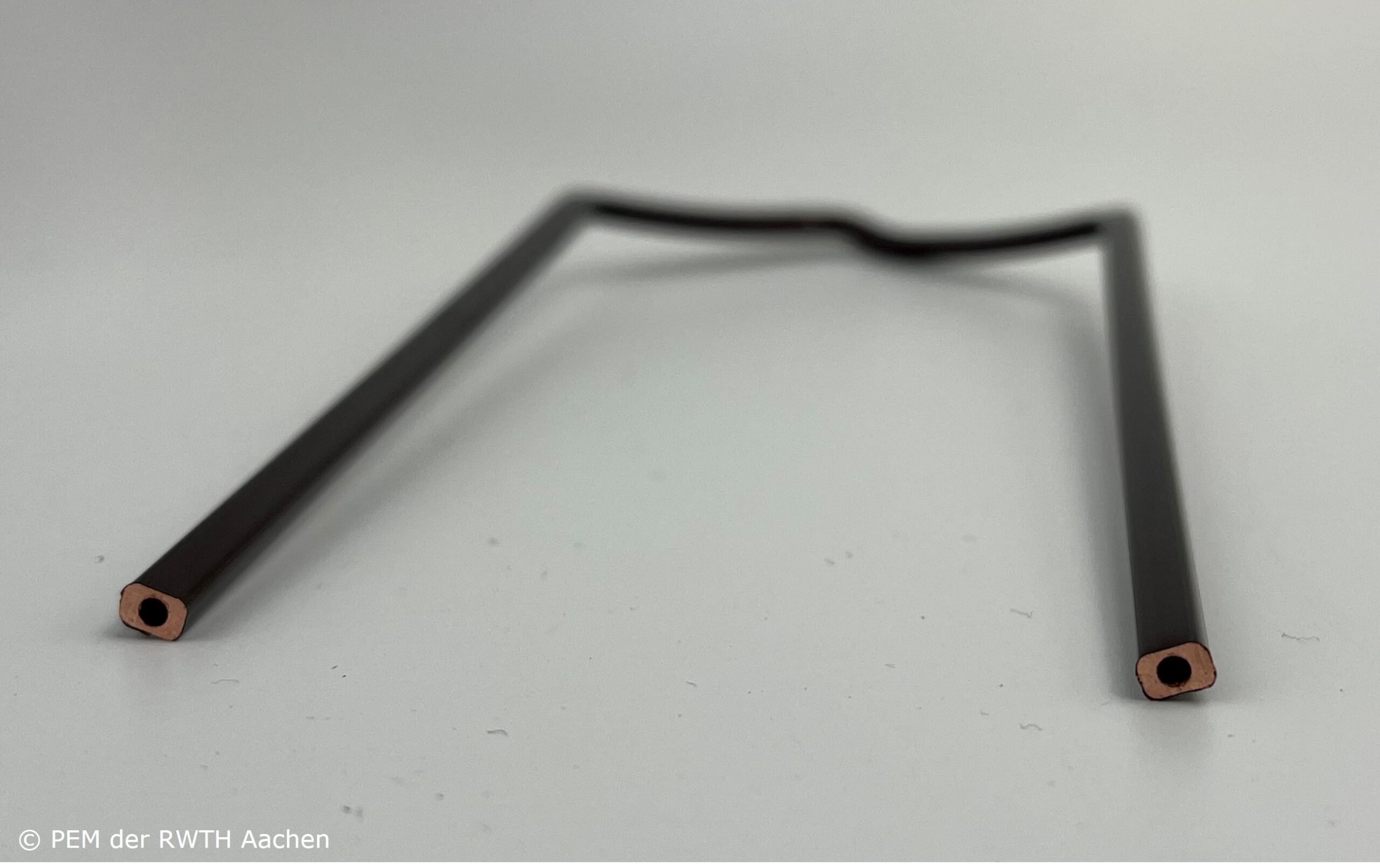

With the layer- adapted winding, a flat, wide conductor geometry is used on the wide outer side of the trapezoidal slot and a narrow, thick cross-section geometry on the short inner side. When designing the conductor cross-sections, the electric conductivity of the conductor cross-section is also taken into account and included in the design phase. The different cross-section geometries of the conductors are produced using IWU’s innovative forming process. The use of forming technology offers numerous advantages. For example, there is no waste that would have to be recycled. Compared to additive manufacturing processes, the energy required for production is also lower and large quantities can be produced with simple tools.

Figure source: https://www.iwu.fraunhofer.de/content/dam/iwu/de/Bilder/Presse/Demonstratorspule-trapezfoermiger-Querschnitt.jpg

Text source: https://www.iwu.fraunhofer.de/de/presse-und-medien/presseinformationen/PM-2023-IWU-Umformtechnik-macht-E-Motoren-leistungsstaerker-und-effizienter.html