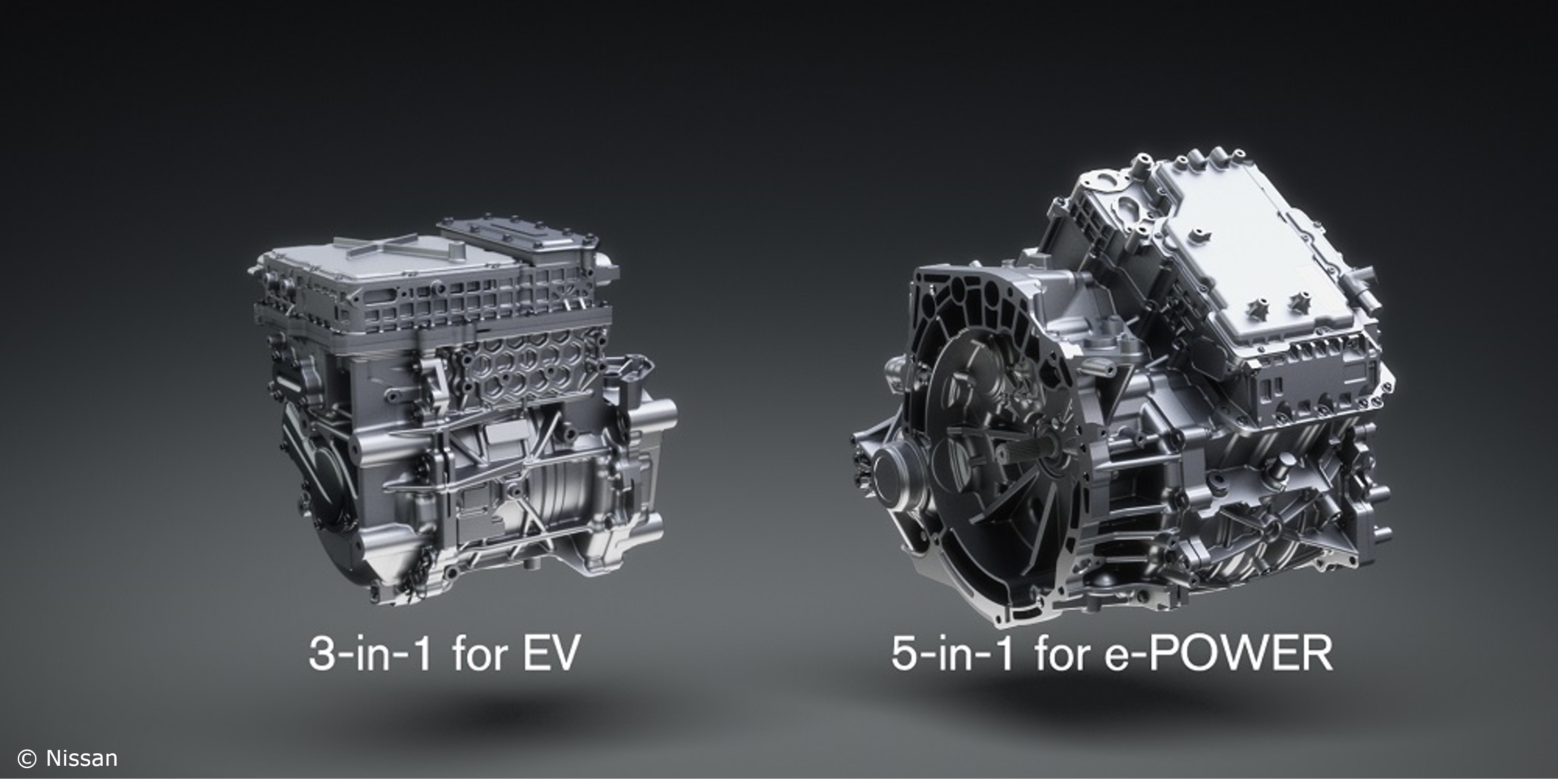

Nissan has presented a modularization approach for new electric drives under the name “X-in-1”. The approach is to be implemented in two powertrains, for purely electric cars as 3-in-1 and for the car manufacturer’s serial hybrids as 5-in-1. The 3-in-1 drive consists of an electric motor, an inverter and a reduction gearbox, while the 5-in-1 drive also includes a generator and a transmission gearbox.

Cost savings of up to 30%

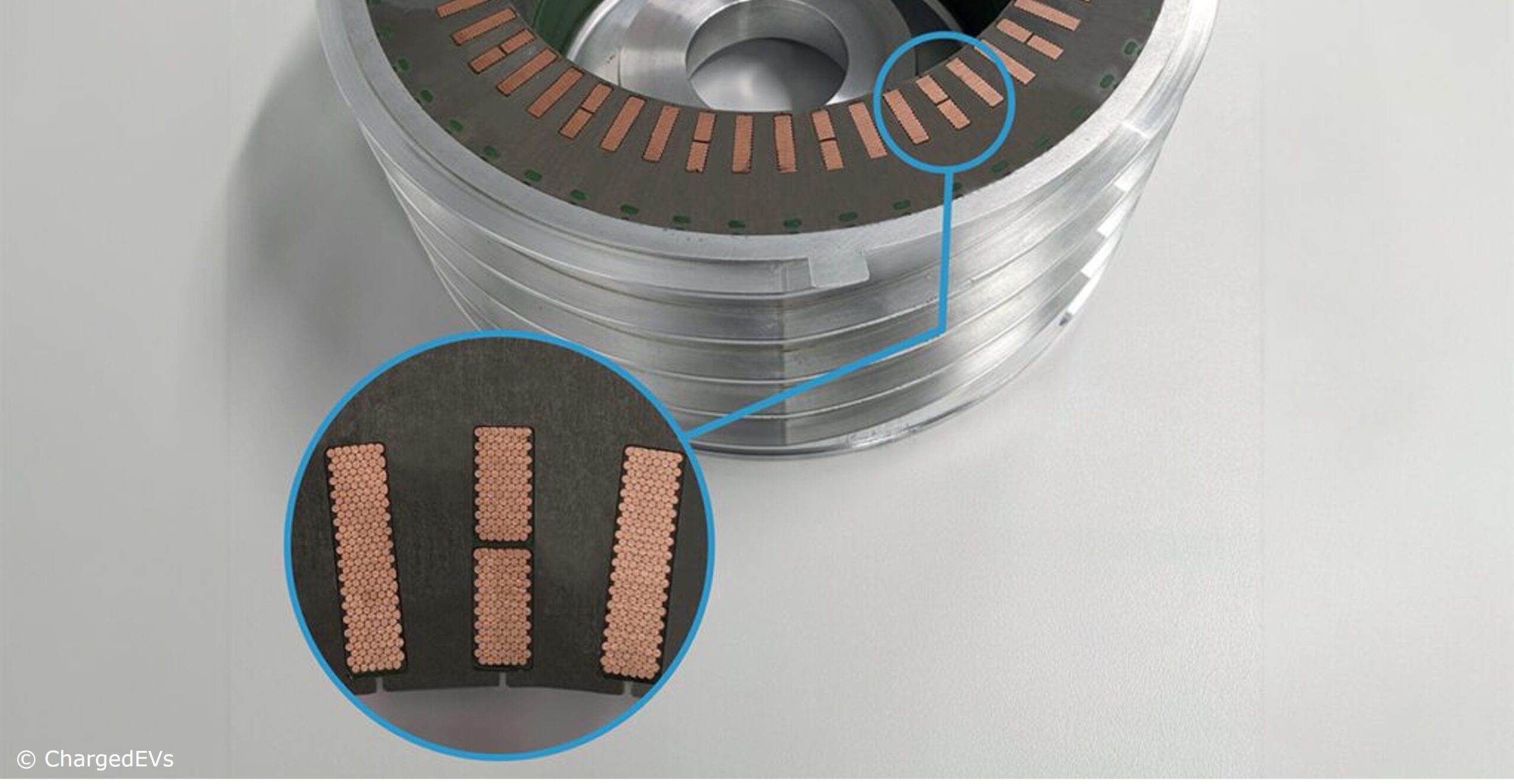

Thanks to the modularization approach, synergies can be used with the X-in-1 drives while the same core components – electric motor, inverter and reduction gearbox – can be used to increase production efficiency and competitiveness. According to Nissan, this is expected to result in cost savings of up to 30% by 2026 compared to the costs of drive units as of 2019. In addition to the modularization approach, the electric motor used has been further developed with sustainability in mind. Nissan claims that the use of rare-earth elements in the electric motor can be reduced to 1% of the original weight through product development.

Development to focus on customer requirements

Both the modularization approach and product development will contribute to the long-term corporate “Nissan Ambition 2030” vision under which the company’s electrified product portfolio is to be expanded by the end of the decade. The focus of development will be on customer requirements.

https://global.nissannews.com/en/releases/nissan-e-power-tech-x-in-1