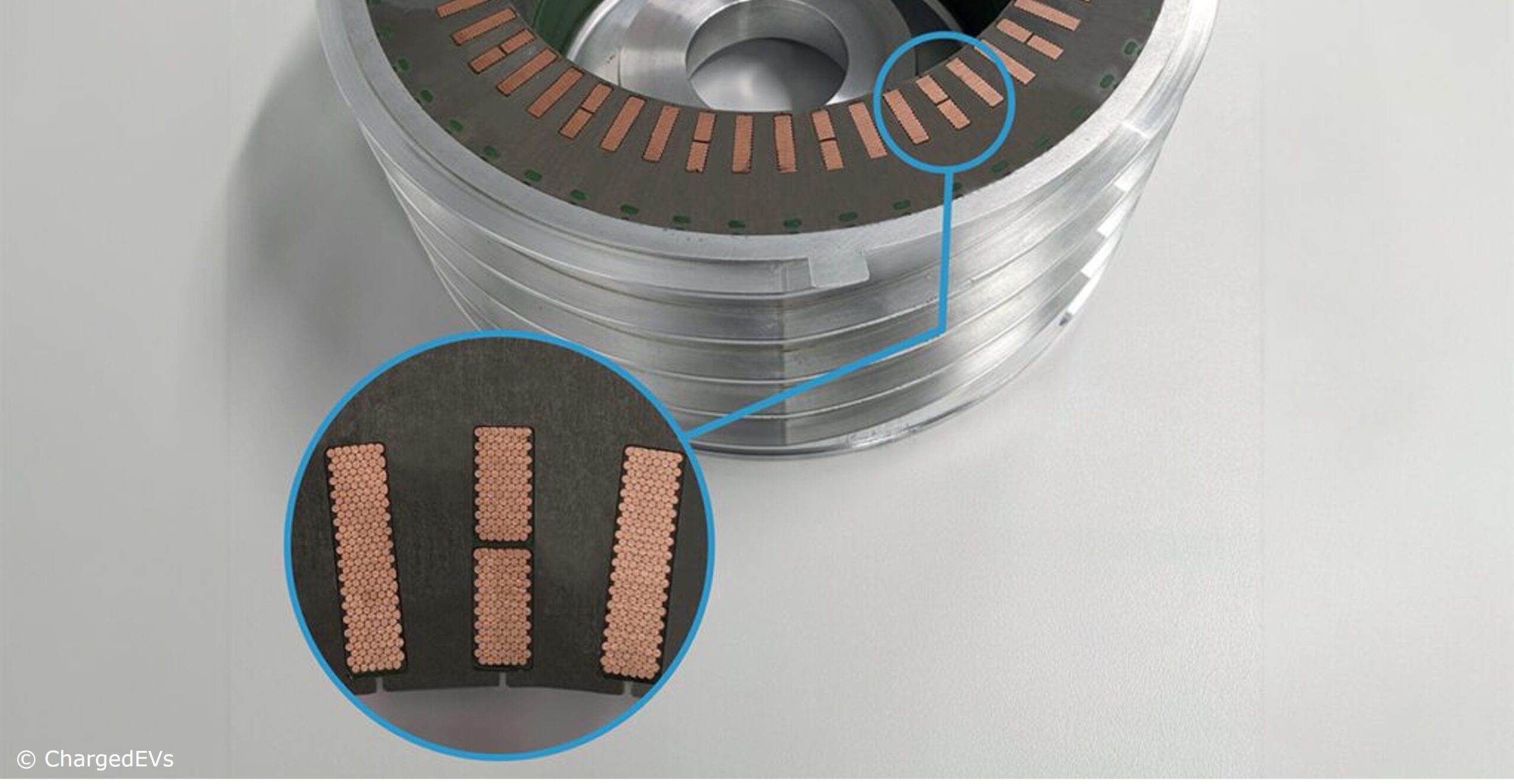

Marsilli, a manufacturer of winding and assembly systems for electric motors, announced the development of Distributed High-Density (DHD) stator winding technology three years ago. Marsilli has now declared the technology mature. The company is involved in several pilot projects and is working with partners and customers on new projects to bring DHD stator winding technology to market.

High slot fill factors and reduced losses

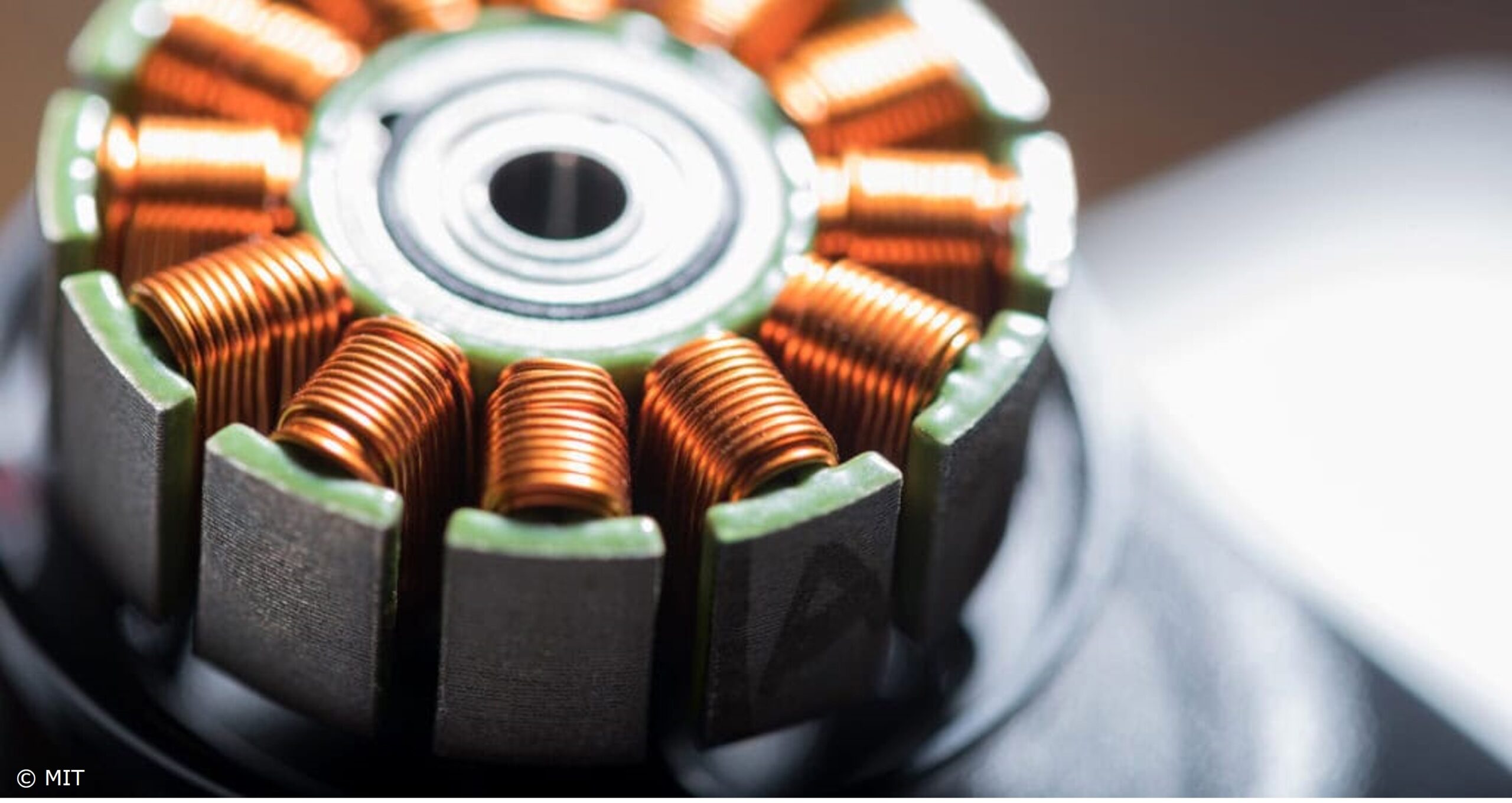

DHD stator winding technology combines the best features of pull-in and hairpin winding technologies and is suitable for a wide range of motor sizes and applications, including electric vehicle traction motors. The technology uses thin, round copper wire wound in a precise pattern to maximise slot fill factor and minimise static copper losses. DHD winding prototypes have already been produced and tested. According to the manufacturer, the result is comparable efficiency at low speeds and up to 6% higher efficiency at higher speeds compared to comparable hairpin motors. The efficiency gains are primarily due to lower AC losses at higher speeds.

Figure source: https://chargedevs.com/wp-content/uploads/2023/05/Marsilli-1024×730.jpg

Text source: https://chargedevs.com/newswire/marsillis-new-electric-motor-winding-technology-demonstrates-superior-efficiency/