German company ZF-Division Commercial Vehicle Solutions has started series production of its “CeTrax lite” electric central drive in Friedrichshafen. The drive was developed for light commercial vehicles in global zero-emission urban and intercity transportation. The first customer to use the drive is Japanese truck manufacturer ISUZU. “CeTrax lite” is intended to enable manufacturers of commercial vehicles to electrify their existing vehicle platforms and support them in implementing locally emission-free transportation.

Optimal installation space and high power density

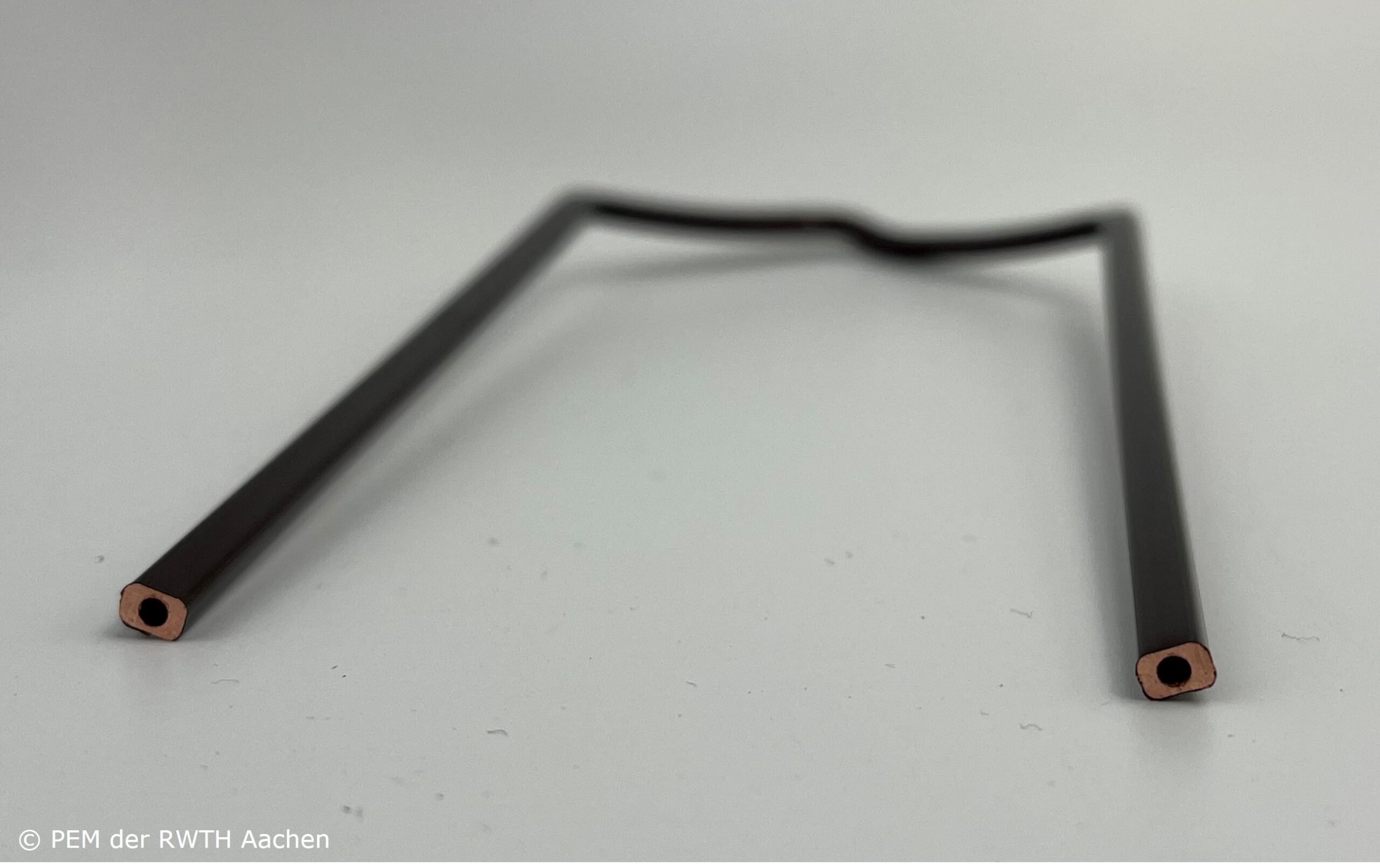

The technology maximizes the available installation space for electrical components and batteries. The module is a fully integrated system that contains the electric motor as well as a reduction gearbox and the power electronics. The new generation of power electronics uses “Discrete Package Technology” to achieve a high degree of component uniformity and adaptability. The electric motor is characterized by a new cooling concept and a new winding technology, which enable a higher power density. ZF’s coaxial reduction gearbox is based on planetary gears and offers weight and installation space advantages without compromising on efficiency and noise development.

Powerful and lightweight drive

The high-voltage converter from ZF’s power electronics platform for fuel cell applications has an efficiency of 99.6%. “CeTrax lite” is designed for light commercial vehicles of up to 7.5 tons and offers a peak output of 150 kilowatts as well as a torque of 1,500 newton meters. The system weighs around 120 kilograms.