As part of the Ultra-Efficiency Factory Innovation Lab (UltraELab) research project, the German Federal Ministry for Economic Affairs is providing ten million euros in funding for the construction of an ultra-efficient factory by 2025. The production facility is to be designed and constructed in collaboration with the Fraunhofer Institute for Manufacturing Engineering and Automation (IPA), the Institute for Energy Efficiency in Production (EEP) at University of Stuttgart, the Institute for Industrial Engineering and Industrial Organization (ifab) at Karlsruhe Institute of Technology (KIT), and Schaeffler Automotive Bühl GmbH & Co. KG.

Digitalization, resilient supply chains and more

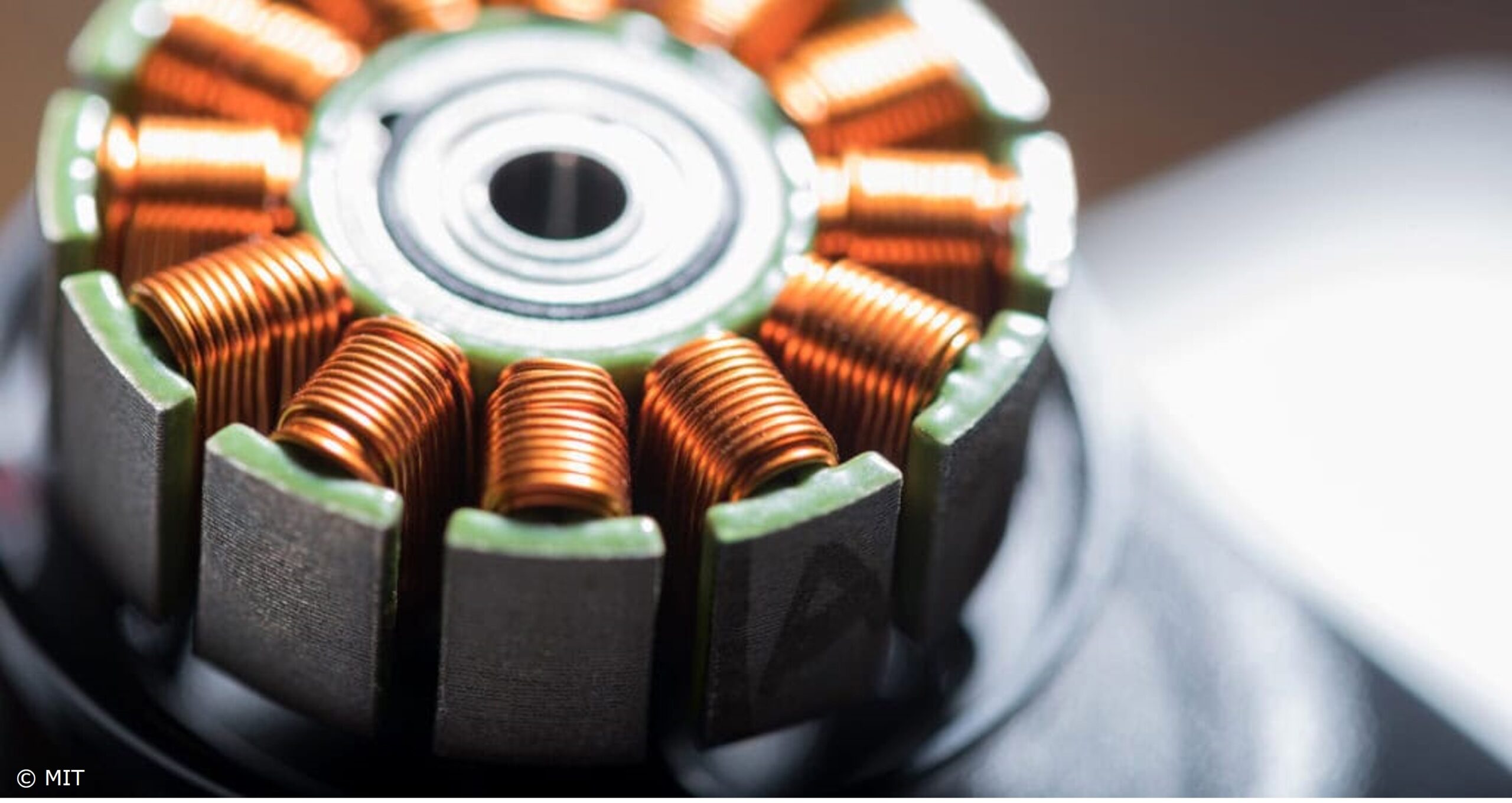

The goal of the ultra-efficient factory is to establish a state-of-the-art, environmentally friendly and competitive production of electric motors. The focus is on aspects such as decarbonization, digitalization, more resilient supply chains with a European location perspective, and progressive internationalization. The concept of the ultra-efficient factory includes a holistic view of production and its environment, taking into account the areas of energy, materials, emissions, people/personnel, and organization. The plan is to identify and exploit optimization potential in all areas, considering the interactions.