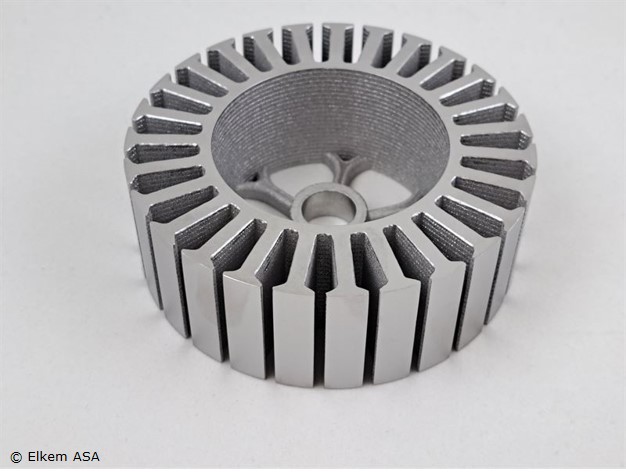

Together with project partners VTT, Siemens, Stellantis and Gemmate Technologies, Norwegian company Elkem has developed a soft magnetic powder for the production of electric motor stators. According to the manufacturer, the powder is based on silicon steel mixed with additives, is processed using powder bed fusion and is easy to magnetize and demagnetize. The innovation was developed as part of the SOMA (“Lightweight Solutions for E-Mobility by AM for Soft Magnetic Alloys”) project which was funded by the EU for three years with a total of 6.3 million euros.

Higher efficiency with less material consumption

The stator lamination stack of today’s electric motors are produced by laser cutting or punching individual segments from a metal sheet and then stacking them. The use of innovative 3D printing technology could significantly increase efficiency in this field of application and considerably reduce material consumption, for example due to sheet metal waste. This technology is particularly promising for smaller stators due to its high flexibility and low tool costs.

Market launch is imminent

To validate the developed material, Siemens produced a motor for an electric scooter. The result was a demonstrator with high mechanical strength, low component weight and competitive electromagnetic properties. Elkem intends the powder’s market launch in small quantities in the near future.

https://www.elkem.com/no/presserom/nyheter/article/?itemid=EE6D7C6E5A12CAE6