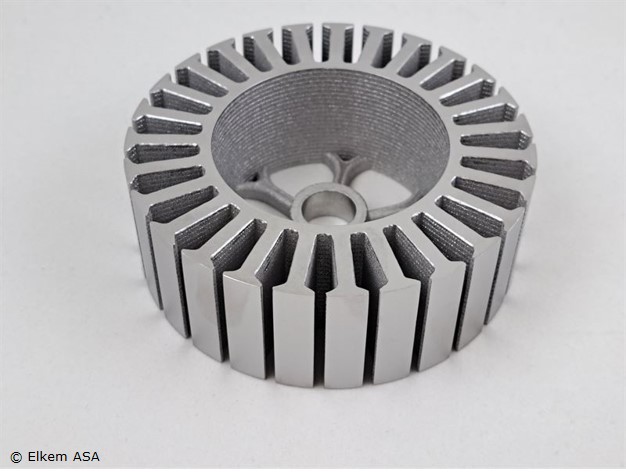

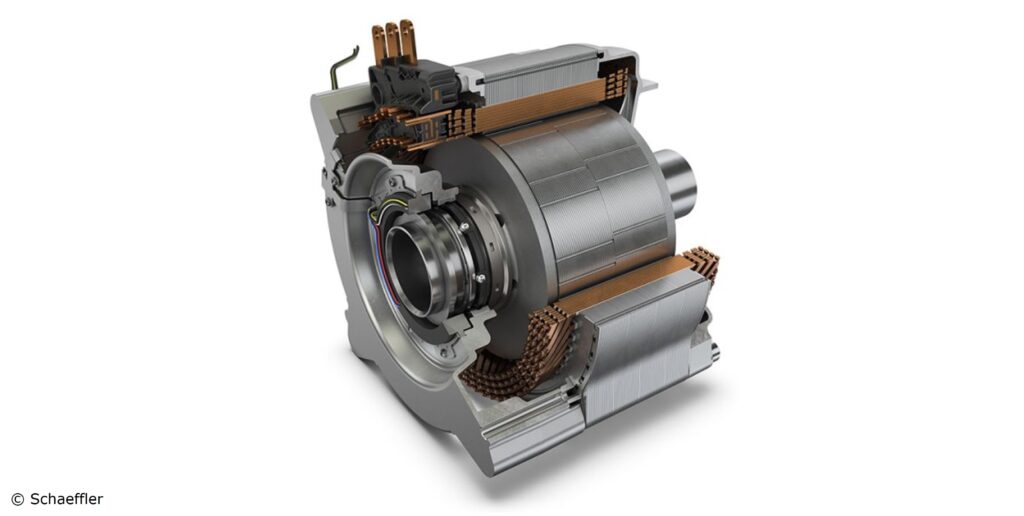

New Magnet Recycling Process Benefits Electric Motors

Researchers at the Fraunhofer Research Institution for Materials Recycling and Resource Strategies (IWKS) in Germany have developed a new recycling method for spent magnets that are used in electric motors. Until now, such magnets were produced under expensive and environmentally harmful conditions and were rarely recycled. The new process makes it possible to produce magnets […]

New Magnet Recycling Process Benefits Electric Motors Read More »