Nissan wants to reduce dependencies with magnets made of iron and samarium

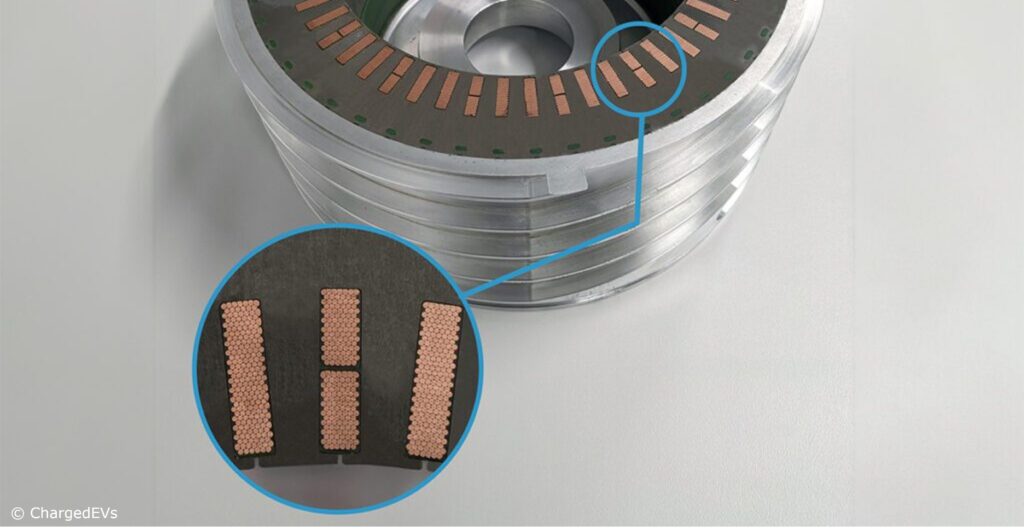

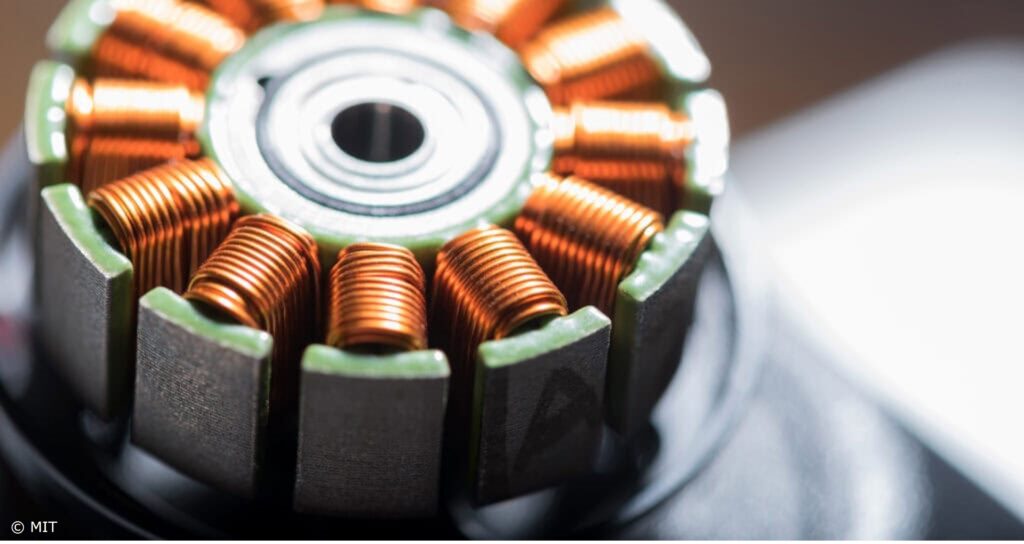

Nissan wants to reduce the production costs of electric cars by 30 per cent over the next few years in order to reach the price level of combustion engines. Among other things, the Japanese car manufacturer is focussing on the permanent magnets used in the rotor, which are made of rare earths. In particular, Nissan […]

Nissan wants to reduce dependencies with magnets made of iron and samarium Read More »